Waiting for imaging would extend the lead time and create unpredictability in the time to create and deliver the implant, a significant issue when surgery had already been scheduled. Solutions like Dropbox weren’t viable given privacy issues.

Another problem was complexity and administrative overhead, compounded by increasing demand for Ossis’s implants. Madeleine noted that “Different viewers, or sometimes hard copies, all added risk and effort to the process.” Without solving the logistical issues that risked pushing lead times beyond four weeks, expanding into other markets beyond Australia was unthinkable.

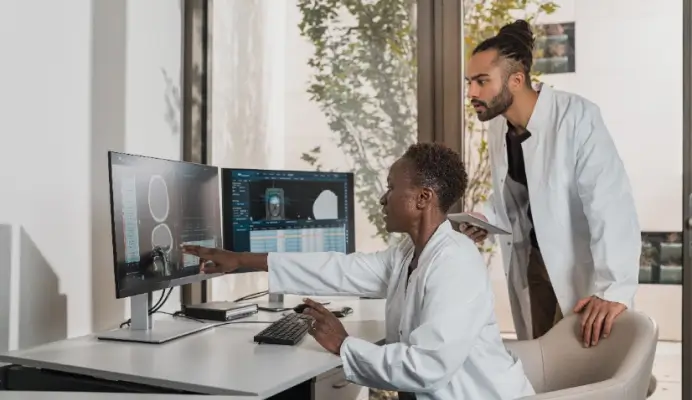

Looking for a better way to manage the logistics around market expansion, the Ossis team started with a trial of InteleShare, enabling the digital instant transfer and routing of imaging, while getting feedback from their agents and surgeons on the new system.

Particularly important was ensuring that it was a full image management solution that could instantly route imaging from surgeon to reviewer, and even send on to suppliers when necessary. Just as important was that it complied with Australia and the regulations of other markets they were eyeing.

Dramatic Lead Reduction

With a positive experience, Ossis expanded their use of InteleShare. They now simply send a link for image upload, eliminating the need for CDs or hard copies. Agents and surgeons can simply login and upload images, while Ossis’ s suppliers can easily download them as necessary too, integrating the whole imaging supply chain. The speed up has been significant, with Madeleine summarizing that “our one week lead time for receiving imaging has now dropped to zero.”